Abstract

Michell Bearings has developed PTFE bearing technology for thrust and journal applications. This type of bearing is known to offer several advantages over the more traditional whitemetal type. The paper describes the PTFE tilting pad thrust bearing together with the key advantages of the product compared with whitemetal. The advantages are demonstrated by a case study involving the retrofit of a problematic whitemetal thrust bearing with PTFE on a pumped storage hydrogenerator. The paper goes on to cover recent developments of PTFE in tilting pad journal bearings.

Introduction

In 1839 an American by the name of Isaac Babbitt invented a bearing alloy that was to later bear his name – Babbitt Metal. More generally known in other parts of the world as whitemetal, the material is an alloy of tin (sometimes lead), copper, and antimony. Tin based whitemetals have been the predominant material for a wide variety of hydrodynamic bearings for many years. Their use for thrust surfaces pre-dates the invention of the tilting pad bearing at the start of the last century. The strengths and weaknesses of the material are well known [1]. On the positive side, whitemetal provides a dimensionally stable surface that is easily repaired or replaced, and it is forgiving in the sense of being able to absorb into its surface hard particles of detritus without causing further damage. On the down side whitemetal has a relatively low melting point and this leads to an upper limit on the temperature possible during hydrodynamic bearing operation. If the limiting temperature is exceeded, catastrophic failure of the bearing is likely to ensue within a very short period of time. The effect of the whitemetal emperature limit is to restrict the maximum duty ( expressed as a combination of speed and load) permissible in any particular bearing. As a further consideration, it can be noted that the main constituent of whitemetal, namely tin, is an expensive commodity which has often been in limited availability in many parts of the world.

With the development of the tilting pad and taper-land hydrodynamic thrust bearing at the beginning of the twentieth century it was natural for engineers to continue to work with the material they knew. Although other materials have been developed for hydrodynamic bearing surfaces, including, for example, copper-lead alloys, whitemetal has remained the world’s preferred choice for most industrial applications.

Almost one hundred years after the invention of whitemetal another significant bearing material was to emerge. In 1938, Dr Roy Plunkett, a worker at the DuPont research laboratories (Jackson Laboratory in New Jersey), was working with gases related to Freon refrigerants. Upon checking a frozen, compressed sample of tetrafluoroethylene, he and his associates discovered that the sample had polymerised spontaneously into a white, waxy solid to form polytetrafluoroethylene or PTFE. The material these days is better known throughout the world by its DuPont tradename of Teflon.

ACCESS FULL

PAPER

Vertical Bearings

Vertical Bearings

Horizontal Bearings

Horizontal Bearings

Tilting Pad Bearings

Tilting Pad Bearings

Marine Bearings

Marine Bearings

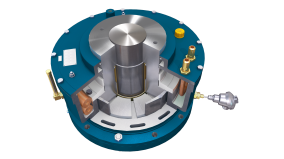

PTFE Bearings

PTFE Bearings PEEK Bearings

PEEK Bearings

Journal Bearings

Journal Bearings

Thrust Bearings

Thrust Bearings