Abstract

In 1995 Michell Bearings commenced a study into the PTFE faced bearing with the objective of producing a commercially available product aimed at the hydro generator market. With collaboration from a leading machine manufacturer and a major end user a full size bearing went into commercial operation in September 1996.

This paper describes in detail the development of this new type hydro generator bearing technology beginning with the testing of a small scale prototype, through to the installation of a full size bearing in a 90 MW pumped storage unit at Ffestiniog Power Station in North Wales, UK. The paper then goes on to describe the development of a PTFE bearing intended for use in the prestigious Dinorwig Pumped Storage Power Station also in North Wales. Details of the results from a limited series of tests in the Dinorwig machine are presented. The effects of a variety of fillers on the friction and wear behavior of the PTFE layer are also reported. The paper concludes with a comment about the environmental benefits provided by the use of PTFE bearings.

Introduction

The PTFE faced thrust pad is not a new concept with respect to hydrodynamic tilting pad thrust bearings. Their use in hydro generator power plant in the former USSR and China is extensive. Outside these countries however little experience exists of their use, and little documentation about them is available.

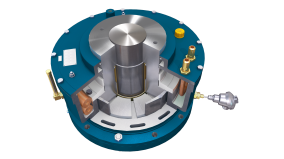

The construction of the bearing is similar in many respects to conventional tilting pad bearings. The pad is generally sector shaped, has sufficient thickness to support the hydrodynamic loading resulting from the sliding motion, relies on some form of pivoting mechanism to produce a convergent film shape, and uses oil as the working medium.

It is the nature of the pad surface however that sets it apart from the more familiar whitemetal or babbitted version. In the latter a relatively thin layer of a tin or lead based alloy is metallurically bonded to the substrate of the pad, often (in the case of older designs) with the addition of dovetail retention grooves. This surface is then machined to a flat or slightly crowned profile. Leading edge chamfers or radii are then added to help induce the hydrodynamic action at start up. In some cases high pressure oil injection is added to assist start up under heavy loading, typically at mean specific loads> 2.4 MPa, or to provide low friction during starting or barring of the machine.

By comparison the PTFE faced pad has a relatively thick layer of a PTFE/wire mesh composite attached to the surface of the pad instead of the whitemetal. The method of bonding the PTFE to the pad is the key to the successful operation of the pad as the wire mesh layer not only provides the means of attachment, but also serves as a compliant layer which allows expansion and contraction of the PTFE in operation. It is worth noting that the coefficient of linear expansion of the PTFE is an order of magnitude greater than that of the supporting steel of the pad. Attachment of the PTFE by adhesives, as is often done in some simple slide bearings used on bridge support bearings for example, would rapidly fail at the joint due to the differential expansion rates encountered at the high sliding speeds typical of hydro generator power plant.

What makes this type of bearing so attractive however is the significantly higher specific loadings that are possible. The reason for this are the unique properties of the PTFE. This in tum confers upon the PTFE bearing a number of benefits. Due to the higher pressures that are now permissible there are reduced power losses, typically 20-30% due to the smaller thrust surface. There is no need for high pressure oil injection. The reduced size also results in reduced costs of the capital plant because of smaller shaft forgings, smaller bearing housing, smaller lubrication system, and a smaller cooler. The bearing has a higher degree of safety margin which leads to increased machine reliability and availability. The material is more forgiving than whitemetal making it ideally suitable for difficult or arduous applications. When combined with a PTFE faced journal bearing the complete bearing is electrically insulated. Finally it is claimed that lower braking speeds are possible due to the superior friction and wear during stopping and starting.

ACCESS FULL

PAPER

Vertical Bearings

Vertical Bearings

Horizontal Bearings

Horizontal Bearings

Tilting Pad Bearings

Tilting Pad Bearings

Marine Bearings

Marine Bearings

PTFE Bearings

PTFE Bearings PEEK Bearings

PEEK Bearings

Journal Bearings

Journal Bearings

Thrust Bearings

Thrust Bearings