Abstract

Technological advances in engineering are frequently driven by the need to solve a particular problem. Successful solutions then form the basis of a new generation of products designed for wider application. This move, from particular to general, is well illustrated by the development of a forced air-cooled, whitemetal bearing able to operate in markedly more extreme conditions than usual. This paper describes the evolution of a bearing design with greatly increased heat dissipation capability when compared with other bearings of its size and type. The resulting operating envelope therefore extends well into the area traditionally occupied by water cooled bearings.

Introduction

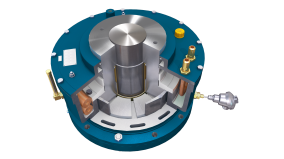

Self-contained, fluid film, tilting pad bearings are standard supply for a wide range of vertical machinery throughout the world. Figure 1 shows a cut away illustration of a typical design of such a vertical bearing with thrust (axial load) and journal (radial load) capability that has been described previously (1, 2, 3). To be self-contained all the lubricant used by the bearing is contained within the casing and it is independent of any external oil supply system. This means that the supply of cooled lubricant to the working surfaces of the bearing is not reliant on an external pump, but rather the rotation of the shaft and its attached collar provide the means of circulation within the casing. The circulation path is shown on the left hand side of Figure 1. Rotation of the lower face of the collar against the non-rotating set of thrust pads acts as a simple pump and oil is forced across the face of the bearing from the inside to the outside diameter.

Constrained within the casing, the oil flows upwards, between the journal pads and back into the oil bath. It is then drawn through channels, not shown in the illustration, situated in the baseplate beneath the thrust pads and back to the inner diameter of the collar. An important feature of the bearing system is the anti-vortex shroud shown on Figure 1 which is fixed to the casing and closely around the upper part of the rotating collar. This prevents the motion of the collar generating a standing vortex in the oil bath.

Of course, considerable heat is generated in the bearing by the viscous shear of the lubricant which takes place in the load carrying fluid film. It is necessary to absorb this heat if the bearing is not to become too hot and most commonly this is done by means of a water cooler immersed in the oil bath around the circumference of the bearing. The right hand side of figure 1 shows part of such a heat exchanger together with one of its connections to an external water supply. Water coolers are typically made from copper nickel alloy tube with externally wound copper wire and situated, as shown, below the level of oil in the casing reservoir.

In installations where an external cooling water supply is unavailable, it is possible for a self-contained bearing to be cooled by heat transfer directly to the surrounding atmosphere. This is achieved by firstly providing the bearing casing with external fins to increase the area from which heat is transferred and, secondly, by arranging for a fan, mounted on the main shaft, to drive air constrained by a cowl at high velocity across this surface. The left hand side of Figure 1 shows a typical arrangement. The enhanced heat transfer coefficients achieved by this method are then usually sufficient for a range of applications with less arduous duty requirements.

The particular case to be described in this paper, however, demanded an air-cooled bearing with a series of duty requirements normally associated with those of a water-cooled bearing. From the outset it was realised that this would be a challenging heat transfer problem, particularly as the range of ambient temperatures fell between -35°C and +30°C. The principal requirement was for a vertical shaft bearing to support a normal downward axial load of 390 kN at an operating speed of 990 rev/min. With a specific load of 3.5 MPa under normal working conditions, the heat generated within the oil bath was calculated to be 9.5 kW. Bearings generating this amount of heat are kept cool either by a continuous supply of cool oil to the bearing from an external source, or by means of a heat exchanger immersed in the oil reservoir as described above. In this case, however, neither external oil nor cool water were available and the client, therefore, requested all heat generated in the bearing be dissipated by heat transfer to the surrounding atmosphere. This was against a background for previous air cooled bearings of similar size where the heat generated was of the order of 3-4 KW. The problem facing designers, therefore, was how to increase the heat dissipation capacity of the bearing to new and unprecedented levels.

ACCESS FULL

PAPER

Vertical Bearings

Vertical Bearings

Horizontal Bearings

Horizontal Bearings

Tilting Pad Bearings

Tilting Pad Bearings

Marine Bearings

Marine Bearings

PTFE Bearings

PTFE Bearings PEEK Bearings

PEEK Bearings

Journal Bearings

Journal Bearings

Thrust Bearings

Thrust Bearings