- About Us

- Bearings

Vertical Bearings

Vertical Bearings

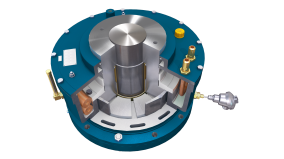

- AV Series

AV Series

A modular range of vertical thrust and guide bearings covering a shaft range of 68-411mm.

- LV Series

LV Series

A modular range of high capacity vertical shaft thrust and guide bearings covering a shaft diameter range of 300-600mm.

- MV Series

MV Series

A bespoke solution specific to vertical shaft machine applications, including combined thrust and guide bearings or guide only bearings.

- V Series

V Series

A modular range of vertical guide bearings covering a shaft diameter range of 96-480mm.

Horizontal Bearings

Horizontal Bearings

Tilting Pad Bearings

Tilting Pad Bearings

Marine Bearings

Marine Bearings

- Marine Gearbox Internals

Marine Gearbox Internals

A range of bespoke internals designed for marine gearboxes.

- Marine Propulsion Motor

and Generator BearingsMarine Propulsion Motor

Propulsion motor and generator bearings for both naval and commercial marine applications.

- Line Shaft Bearings

Line Shaft Bearings

Three ranges of standard horizontal bearings for line shaft applications.

- Thrust Blocks

Thrust Blocks

Main propulsion thrust blocks for all types of surface ships and submarines.

PTFE Bearings

PTFE Bearings PEEK Bearings

PEEK Bearings

- Applications

- Bearing Testing

- Repair and Service

- Careers

- Media Centre

- Contact Us

Journal Bearings

Journal Bearings

Thrust Bearings

Thrust Bearings