Journal pad bearings are widely used in industry, particularly in high-speed applications. Previous experimental work with bearings of this sort has tended to be fragmented and mainly confined to smaller and relatively light loaded bearings. The purpose of this paper is to present temptature measurements and derived values of power loss from a new, extensive experimental program involving a 200 mm diameter journal pad bearing, operating at speeds up to 105 m/s and loaded at specific pressures up to 4.14 MPa. The program was designed to isolate some important design parameters and determine their effect on bearing tempatures and energy consumption. Bearing clearance, journal pad preload, the direction of the applied load, and the impact of radically reducing the amount of lubricant supplied to the bearing are all examined. In particular, it is found that load line direction has a substantial impact on maximum pad tempature. It is also shown that large reductions in the volume of oil supplied to the bearing are possible, leading to useful energy savings without comprimising reliability. One of the most interesting features of the results presented is the significant effect on pad temptature of an apparent laminar to turbulent transition in the lubricant which occurs at high operating speeds. It is hypothesised that the transition takes place in the oil which flows around the pads rather in the hydrodynamic films. It is anticipated that the information contained in the paper will be of interest and use to members of the academic community, bearing designers, and bearing operators.

Introduction

Tilting pad journal bearings are well established as an important design option particularly appropiate for high-speed applications. The results of experimental work with bearings of this sort have been presented previously by a number of authors (1) – (6). While all the papers are useful in their own right, taken collectively the published information is somewhat fragmented. None of the available reports provides a comprehensive investigation into the effects that design variables, such as clearance ratio, pad preload, load direction, and oil flow, have on bearing temperatures and energy consumption.

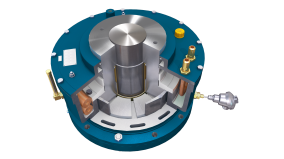

The purpose of this paper is to present the results of a recent wide ranging program of experimental work with a 200 mm diameter, five-shoe tilting pad bearing. The experimental program was designed to complement exisiting work and fill gaps by providing measurements of journal pad tempature over significant ranges of speed and applied load which extend to duties which might be associated, for example, with a high-speed gearbox. Lubricant supply and drain tempatures have also been monitored and used in conjunction with oil flow to derive figures for the energy absorbed by the bearing. Where possible comparions are made with published experimental work, and the influence of the design variables mentioned above is evaluated.

ACCESS FULL

PAPER

Vertical Bearings

Vertical Bearings

Horizontal Bearings

Horizontal Bearings

Tilting Pad Bearings

Tilting Pad Bearings

Marine Bearings

Marine Bearings

PTFE Bearings

PTFE Bearings PEEK Bearings

PEEK Bearings

Journal Bearings

Journal Bearings

Thrust Bearings

Thrust Bearings