Abstract

The use of PTFE faced pads in large vertical axis hydro-generators was pioneered in Russia in the 1970’s, prompted by a series of failures of conventional babbitt-faced bearings. Some advantages claimed include higher specific loading, lower power loss and the omission of oil-lift facilities. There is strong interest in the industry concerning this material, but limited data are available on actutal performance. Some results from extensive testing of PTFE faced pads are given, for two sized of pad. These are compared directly size for size with results for babbitt bearings of nominally the same area. The power losses for the two types of bearing were found to be almost identical. Some of the effects observed during testing are described and discussed, including the effect of creep. The test results are compared with predictions using the GENMAT analysis software. A method of allowing for creep in numerical modeling is discussed.

Introduction

PTFE (polytetrafluoroethylene) is usually classified as a material for use in dry sliding applications. The coefficent of friction against steel can be as low as 0.05, dependent on load and surface finish, and the rate of wear can be very low. There are numerous practical applications of the material, ranging from bushes for aircraft control linkages to prosthetic joints. The wear rate drops to a steady value when a transfer film has formed on the counter-surface. Lubricants were known to interfere with the formation of a transfer film, and grease or oil lubrication were rarely used in PTFE metal contacts.

A major departure from use as dry-slidding material has been the development in the 1970’s of PTFE-faced thrust bearings in hydro generators, in the former Soviet Union and the Peoples Republic of China (PRC). The pads run fully immersed in mineral oil, and in many cases the only change made was to remove the babbitt from pads and replace it with PTFE. Prior to this application of PTFE (according to Alexandrov [1] and Shen [2]), the usual type of bearing had disk-supported babbitt-faced pads, which were quite lightly loaded as judged by modern standards. Following demands from increased power, nation-wide programs were enacted to upgrade hydro generators. Shen [2] gives an interesting account of the problems that occured in China, for example ‘break-down occured in almost every hydroelectric unit through the 1970’s’. The upgrade called for an increase of PV from (typically) less than 50 MPa.m/s to 55 – 91. The most usual problem was high tempature in the center and center-trailing areas of the pad, apparently due to excessive crowning. This led to wiping of the central areas of the pads and subsequent cascading damage from pad to pad as smeared babbitt from one pad broke away and entered the film of the following pad. Simmons et al. [3] give an extended review.

At present PTFE pads with loading as high as 10.2 MPa are in use, although most PTFE bearings are run at pressures only slightly higher than the babbitt bearings that were replaced. According to numerous reports (many of which are not formally published) the replacement with PTFE-faced pads ‘completely eliminated the wiping-out problem’ and allowed the development of bearings of 3000 – 4000 tonnes capacity. It is reported that as present over 80% of hydro generators in the former Soviet Union have this type of bearing, and at least 400 units in the PRC. These developments have attracted strong interest in the Industry in Europe and the Americas but few data are available. Some units in the UK and Ontario have been retrofitted with PTFE–faced thrust bearings, as described by Simmons et al. [3], Knox [4], and Mohino et al. [5]. However few direct comparisons have been made between PTFE-faced and babbitt-faced bearings. This paper gives size for size comparisons for two bearing assembies with pads of approximately 130 mm x 140 mm and 306 mm x 260mm size. The PTFE and babbitt bearings were tested in sequence in the same test machines.

ACCESS FULL

PAPER

Vertical Bearings

Vertical Bearings

Horizontal Bearings

Horizontal Bearings

Tilting Pad Bearings

Tilting Pad Bearings

Marine Bearings

Marine Bearings

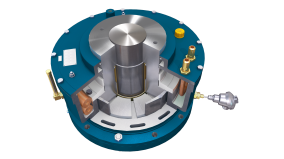

PTFE Bearings

PTFE Bearings PEEK Bearings

PEEK Bearings

Journal Bearings

Journal Bearings

Thrust Bearings

Thrust Bearings