All hydrodynamic bearings require a continuous supply of cooled lubricant. In the case of large, high speed electric motors for industrial applications, oil is most commonly provided by an external lubrication system design to API or equivalent specifications. This paper describes the design and some of the experimental work done in the development of a new range of self contained, air cooled bearings designed to eliminate the need for such costly external lubrication systems. Experimental work was carried out using a 140 mm shaft diameter test bearing operating at a range of duties up to a maximum specific load of 2.07 MPa and a maximum speed of 4500 rev/min. Measurements made include those for oil delivery against speed utilising an innovative, dual mode oil ring described in the paper.

Introduction

Hydrodynamic bearings are fined to high speed, horizontal shaft, electric motors for a very wide range of industrial applications in preference to rolling element bearings for reasons of longer life and greater reliability. In every application, satisfactory hydrodynamic bearing performance requires ensuring an adequate system for oil supply to the working faces and managing the disposal of heat generated in the bearing. Typical smaller and lower speed machines use an oil ring, which may hang loosely on the shaft or be fixed to it to generate oil circulation within the bearing, and fins on the casing to dissipate the heat generated. The effectiveness of the oil ring and the limitation of casing surface area are obstacles to extending the simple oil ring concept to larger and faster machinery. For example, difficulties due to high ring speeds and a reduction in oil delivery rate start to appear in two pole motors at shaft diameters above I00 mm. The problem may well be exacerbated if the surface area of the casing is restricted by a centre flange mounting.

In previous designs it has been usual when these oil delivery and casing surface area limits have been encountered 10 employ a completely separate oil conditioning system to provide cooled lubricant to the bearing. Oil conditioning units, combining the functions of oil circulation and cooling, are generally provided in accordance wilh API specification 614 which implies the design of complex systems to ensure a reliable supply of oil. The purpose of this paper is to describe the design and underpinning experimental work behind the development of a new range of completely self-contained, air cooled bearings which extend the envelope of machinery size and speed which can be air cooled without the costly overhead of external oil conditioning systems.

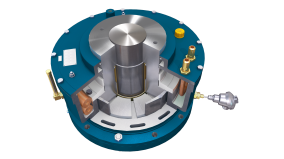

The internal circulation system for the new bearings makes use of an innovative dual mode oil ring in which oil is collected both from the outside of lhe ring at start up and run down and from inside the rim of the oil ring at operating speed. Oil collected in this latter fashion is conveyed under self generated pressure to an external air blast cooler before being returned to the bearing, still under pressure and in quantities equivalent to those provided by a conventional lubrication system. Figure 1 shows a schematic diagram to illustrate the principle of the dual mode oil ring. Details of its embodiment in a practical bearing design are given in the next section.

ACCESS FULL

PAPER

Vertical Bearings

Vertical Bearings

Horizontal Bearings

Horizontal Bearings

Tilting Pad Bearings

Tilting Pad Bearings

Marine Bearings

Marine Bearings

PTFE Bearings

PTFE Bearings PEEK Bearings

PEEK Bearings

Journal Bearings

Journal Bearings

Thrust Bearings

Thrust Bearings