- About Us

- Bearings

Vertical Bearings

Vertical Bearings

- AV Series

AV

LV SeriesLV

MV SeriesMV

V SeriesV

Horizontal Bearings

Horizontal Bearings

- HD Series

HD

IH SeriesIH

Tilting Pad Bearings

Tilting Pad Bearings

Journal Bearings

Journal Bearings

- Journal Pad Units

Journal

Thrust Bearings

Thrust Bearings

- SE Series

SE

Omega EqualisedOmega

OmegaOmega

Marine Bearings

Marine Bearings

- Marine Gearbox Internals

Marine

Marine Propulsion Motor

and Generator Bearings

PTFE Bearings

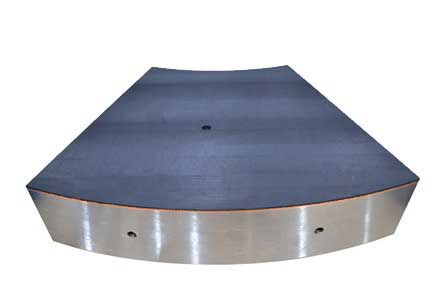

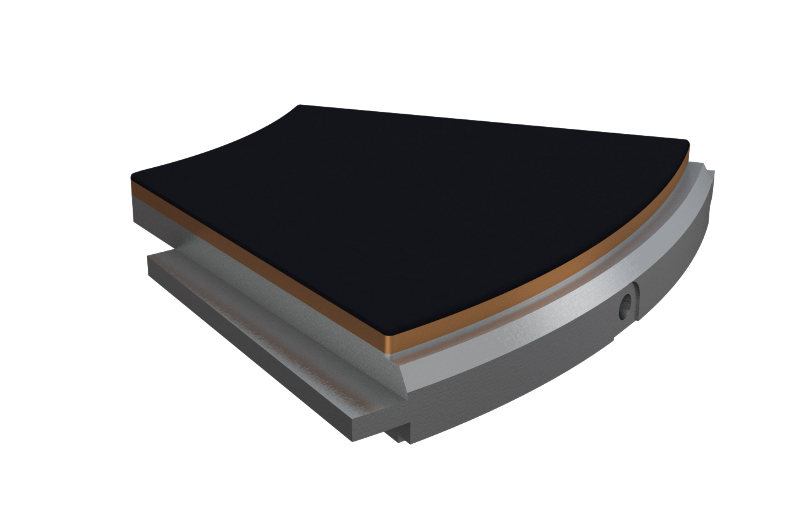

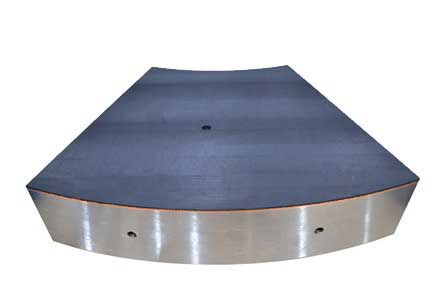

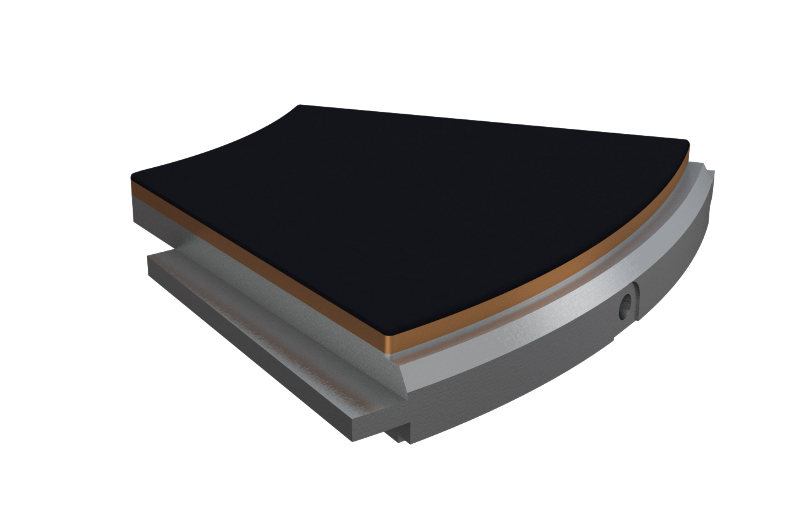

Our development of PTFE bearings began in the mid 1990s. Investigative test work established that the material could operate without undue wear and at specific loads, significantly higher than that of white metal bearings, without high pressure oil injection.

The ability of the PTFE material to operate safely at minimal oil film thicknesses, allows approximately twice the specific load capacity normally associated with white metal. Our initial PTFE project work concentrated on large thrust pad sizes used in hydro-generator applications, whereby advantages of PTFE could improve the reliability of problematic machines. Today PTFE is often specified as first choice for hydro-applications and has been shown to have clear advantages for small pad applications in more standardised reversing pump applications.

Our PTFE bearings are similar in construction and operation to white metal pads, except that the white metal layer is replaced by a composite layer of compressed copper wire and PTFE. Using similar proven manufacturing techniques to those used for thrust pads, we are able to bond the PTFE/copper composite to a curved journal bearing surface. This ensures that the required bond strengths are maintained and the PTFE’s properties are not affected.

PTFE lined journal pads can be manufactured across a range of sizes and are suitable for high speed gear box applications, in addition to the more usual large diameter hydro-generator bearings.

Enquire nowThe below key features describe the benefits of PTFE material when compared to white metal:

- Increased load carrying capacity

- Higher durability

- Increased safety factors

- Longer life

- Smaller and lighter bearings

- Reduced power losses

- Superior friction and wear characteristics

- Lower breakout torque

- Complete elimination of high pressure (HP) oil injection

- Highly “forgiving” material

- Ideal material for problematic white metal applications

- No catastrophic failure mechanism

News

Michell Bearings

Waldridge Way,

Simonside East Industrial Park,

South Shields,

NE34 9PZ.Tel: +44 (0) 191 273 0291

Email: sales@michellbearings.com

Email: hrteam@britishengines.com

Email: recruitment@britishengines.com© Michell Bearings.

Registered Office Address: 11 Glasshouse Street, St Peter's, Newcastle upon Tyne. NE6 1BS. Company registered in England and Wales no. 9390648

PTFE Bearings

PTFE Bearings